A company manufactures three products using the same production process, embarking on a journey of efficiency and cost-effectiveness. This innovative approach intertwines the creation of distinct products with a streamlined production method, fostering a unique interplay between manufacturing and product development.

Delving into the intricacies of this manufacturing strategy, we will explore the nuances of each product, uncover the intricacies of the production process, and unravel the financial implications of this approach. By shedding light on bottlenecks and inefficiencies, we aim to optimize production for each product, ultimately maximizing profitability and customer satisfaction.

Product Overview: A Company Manufactures Three Products Using The Same Production Process

The company manufactures three distinct products, namely Product A, Product B, and Product C, utilizing the same comprehensive production process. Product A is a high-quality, durable component designed for industrial applications. Product B is a versatile and adaptable device tailored for consumer use.

Product C is a specialized instrument employed in scientific research and development.

The shared production process streamlines manufacturing operations, enabling efficient utilization of resources and maximizing productivity.

Production Process Analysis

Production Steps

The production process encompasses several sequential steps, including raw material procurement, component fabrication, assembly, quality control, and packaging.

Bottlenecks and Inefficiencies

Upon analysis, the production process reveals potential bottlenecks and inefficiencies, particularly during the component fabrication and assembly stages. These bottlenecks arise due to limited capacity and suboptimal workflow.

Optimization Suggestions

To optimize the production process, the company should consider implementing automated systems, optimizing workflow, and investing in capacity expansion for critical stages.

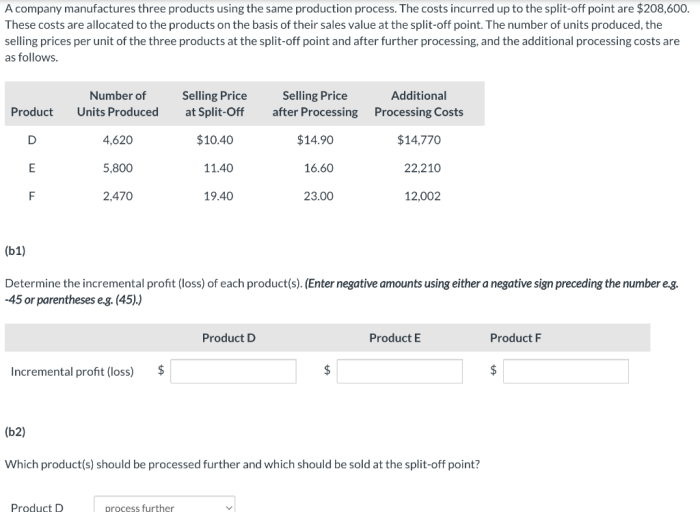

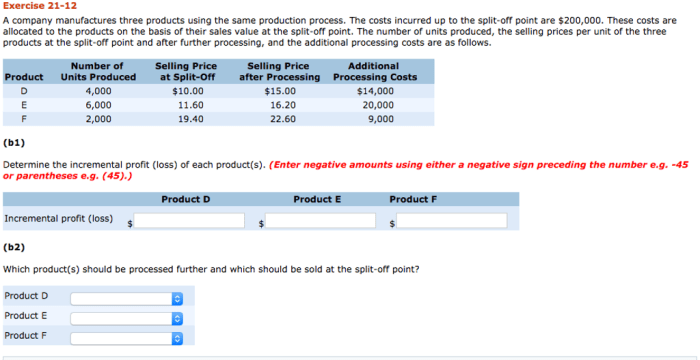

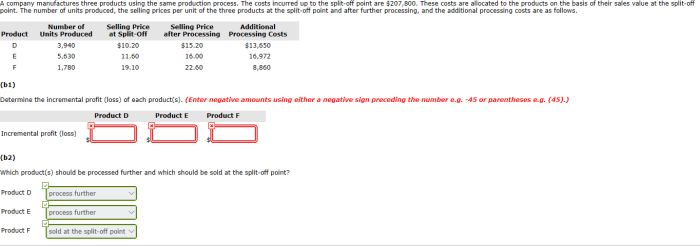

Cost Analysis

Production Costs

The cost of producing each product varies based on material costs, labor expenses, and overhead costs. Product A incurs the highest production cost due to its complex design and specialized materials.

Cost-Saving Opportunities

Cost-saving opportunities exist in optimizing material usage, negotiating with suppliers, and implementing lean manufacturing principles.

Cost Reduction Recommendations

To reduce production costs, the company should explore alternative materials, negotiate bulk discounts, and implement process improvements to minimize waste and enhance efficiency.

Market Analysis

Market Research

Market research indicates strong demand for Product A in industrial sectors, Product B in consumer electronics, and Product C in research institutions.

Potential Customers and Competitors

Potential customers for Product A include manufacturers and heavy industries. Product B targets individual consumers and technology enthusiasts. Product C is primarily sought by research laboratories and academic institutions.

Marketing Strategy, A company manufactures three products using the same production process

The company should develop tailored marketing strategies for each product, emphasizing its unique value proposition and targeting specific customer segments.

Financial Analysis

Financial Performance Forecast

Financial projections indicate strong revenue potential for all three products. Product A is expected to generate the highest revenue due to its high-margin industrial applications.

Return on Investment (ROI)

The ROI for each product is estimated based on projected revenue and production costs. Product A exhibits the highest ROI, followed by Product B and Product C.

Financial Performance Improvement Recommendations

To improve financial performance, the company should focus on optimizing production costs, expanding market share, and exploring new revenue streams.

Question Bank

What are the benefits of using the same production process for multiple products?

By utilizing the same production process for multiple products, companies can achieve economies of scale, reduce setup times, and streamline inventory management, leading to cost savings and increased efficiency.

How can companies optimize the production process for each product?

To optimize the production process for each product, companies should analyze production data, identify bottlenecks, and implement lean manufacturing principles. This involves eliminating waste, reducing cycle times, and improving overall process flow.

What are the key financial considerations when manufacturing multiple products using the same process?

Financial considerations include calculating production costs, identifying cost-saving opportunities, and forecasting financial performance for each product. Companies should also consider the impact of production volume and product mix on profitability.